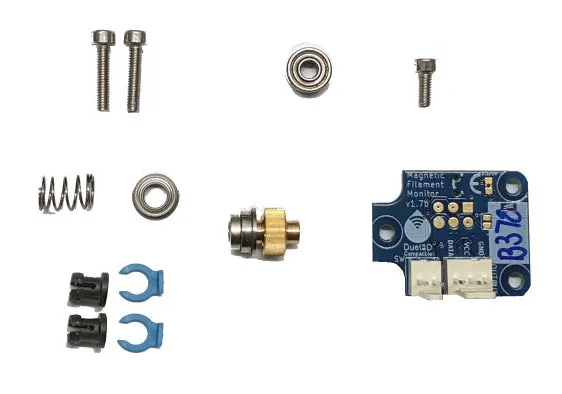

The Duet3D filament monitors sense filament movement and so can indicate a that filament has run out, jammed or has been ground away in the extruder. This is the magnetic filament monitor version . So called because it uses a rotating magnet to very accurately detect movement.

The printed parts are not supplied; the housing models are available here and should be printed with a layer height of 0.2mm (including the first layer). This will ensure the correct distance between the magnet and the sensor PCB.

The filament monitor consists of a PCB which senses the rotation of a diametrically magnetised magnet. That magnet is in turn rotated by the filament motion via a hobbed part. The angle is reported to the Duet

Please read over the documentation on Duet3D's site as this is a more advance feature to implement.

![Balmar Alternator 250 AMP Kit 12V 3.15" Dual Foot Saddle K6 Pulley Regulator Temp Sensor [XT-CR-250-K6-KIT] Balmar Alternator 250 AMP Kit 12V 3.15" Dual Foot Saddle K6 Pulley Regulator Temp Sensor [XT-CR-250-K6-KIT]](https://www.home3dprinti.shop/image/balmar-alternator-250-amp-kit-12v-315quot-dual-foot-saddle-k6-pulley-regulator-temp-sensor-xt-cr-250-k6-kit_PJDel9_285x.webp)